Closed Loop Hot Water Recirculation Line Diagram – Recirculating System Diagram

Water heating is an essential service in every home today, but having to wait for water to heat up before it gets to your home is both time-consuming and inefficient.

Undefined These systems are comfortable and convenient and also help save water by making hot water easily available. Of these systems, the closed loop hot water recirculation system is particularly efficient and effective.

What is a Closed Loop Hot Water Recirculation System?

A closed loop hot water recirculation system is a technique of making hot water available at the tap as soon as possible by circulating the water in a closed loop from the water heater to the faucets.

While an open loop system uses the cold water supply line as the means of recirculation, a closed loop system employs a separate return line.

This setup not only enhances efficiency but also minimizes the wastage of water in the process.

Read More: How Deep to Bury Water Line – Water Line Burial Depth

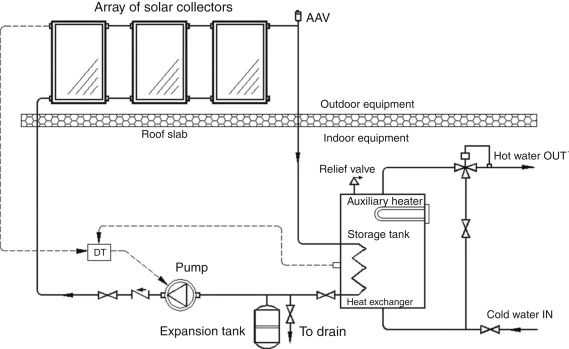

Key Components of a Closed Loop Hot Water Recirculation System:

Water Heater: It warms the water to the right temperature and provides it to the system.

Hot Water Supply Line: Transports hot water from the water heater to other fixtures such as taps, shower etc.

Recirculation Pump: Uses hot water circulation to ensure that hot water is always in circulation in the pipes so that when one needs hot water, it does not take long to be supplied.

Return Line: A pipe that carries water that has been cooled at the farthest fixtures back to the water heater to be reheated.

Check Valve: Helps to prevent backflow of water in the system by allowing water to flow in one direction only.

Thermostat/Temperature Sensor: Keeps track of the water temperature and regulates the operation of the recirculation pump to ensure the temperature in the system is optimal.

Control System/Timer: Controls the circulation pump in that it can be set to run at specific times or when there is a need to do so, to reduce energy consumption.

Mixing Valve: Optional A valve that mixes hot water with cold water to ensure that the water is safe and at the right temperature when it gets to the fixtures.

Diagram Description:

- The water heater is linked to the hot water supply pipe.

- Water is supplied through the supply line and it is hot water that goes to the fixtures.

- At the farthest fixture, a return line carries the cooled water back to the water heater.

- A recirculation pump in the return line will guarantee constant circulation.

- These are located at appropriate positions to ensure that backflow is not allowed to occur.

- There is a thermostat near the pump which regulates the temperature and the working of the pump.

Operation of the Closed-Loop System

Heating the Water: The water heater warms the water to the required temperature. Hot water is then forced into the hot water supply line.

Circulating the Hot Water: The recirculation pump pumps hot water through the supply line and back through the return line constantly. This means that hot water is always available at all fixtures without much time being taken when a tap is opened.

Monitoring and Feedback: The thermostat or temperature sensor checks the temperature of the water in the supply line or at a certain point in the system at all times. If the water temperature falls below a set limit, the system turns on the recirculation pump or keeps it on.

Adjusting Based on Feedback: The temperature data is then utilized by the controller to control the pump’s function. If the water is already at the right temperature, then the pump may be slowed down or even stopped to save energy. These are used to allow water to flow in the right direction and not allow cold water to mix with the hot water supply.

Demand Control (Optional): In systems with a control system/timer, the recirculation pump may run on a time-based schedule (e.g., during periods of high usage) or on-demand (when a hot water fixture is used).

This demand control ensures that water circulation is only done when needed and not all the time hence saving energy.

Return of Cooled Water: Water that has cooled down in the supply line is then sent back through the return line to the water heater for reheating, thus no water is wasted.

Energy Efficiency Considerations:

- Energy Efficiency Considerations: Timers and Smart Controllers: To improve energy efficiency, the system can be set to operate only during peak times or when hot water is likely to be used, rather than running continuously.

- Insulation: Pipes are often insulated to reduce heat loss during circulation, which also helps in maintaining the desired temperature and reducing energy consumption.

This continuous monitoring and adjustment, characteristic of closed-loop systems, ensures that the hot water is always available when needed, while also optimizing energy and water use.

Advantages of a Closed Loop System

Water Conservation: A closed loop system significantly reduces water waste by eliminating the need to run the tap until hot water arrives.

Energy Efficiency: Though the pump uses energy, the system is designed to minimize overall energy use by keeping water hot within the loop.

Immediate Hot Water Availability: One of the most notable benefits is the immediate availability of hot water, enhancing comfort and convenience.

Installation Process of a Closed Loop Hot Water Recirculation System

Plan the System Layout: Decide where the water heater, pump, and return line are to be located.

Install the Pump: Fit the pump to the hot water pipe close to the heater.

Connect the Return Line: Run the dedicated return line from the last fixture back to the water heater.

Install the Check Valve: Make sure that it is installed in the right position to avoid back flow.

Connect the Thermostat: Adjust the thermostat to regulate the water temperature.

Test the System: After that, turn on the system to check if all the connections are correct.

Tools and Materials Needed

- Pipe cutter

- Wrench set

- Plumbing tape

- Check valve

- Thermostat

- Water pump

- Piping for the return line

In conclusion, a closed loop hot water recirculation system provides an extremely instantaneous supply of hot water while conserving water and energy through controlled wired piping.